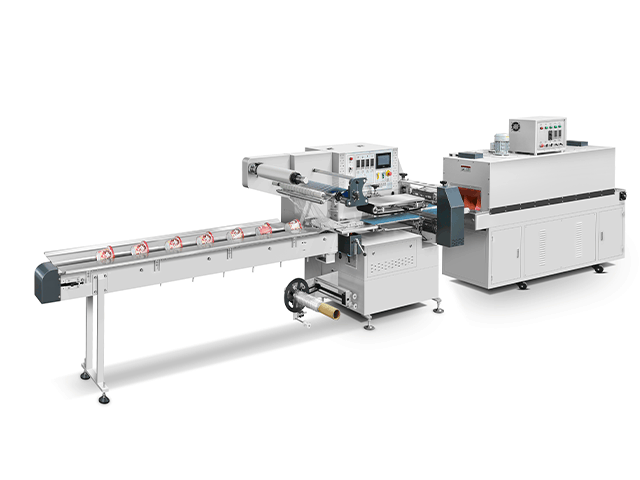

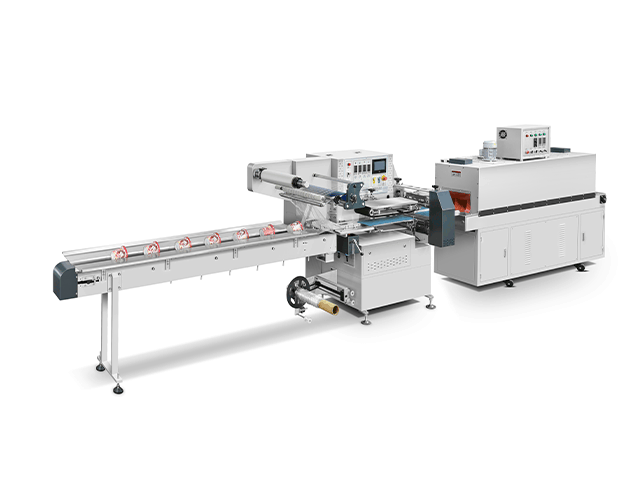

Automatic high speed shrink packing machine including high speed flow type packing machine, continuous motion flow type packing machine and electrostatic adsorption type packing machine which are widely applicate in food, cosmetic, daily chemical, medical, automobile accessory, toy industries. The machines are controlled by servo motors with PLC touch screen, ensuring the machine work very stable and convenient. Mahine work with fast packing speed and saving film cost.

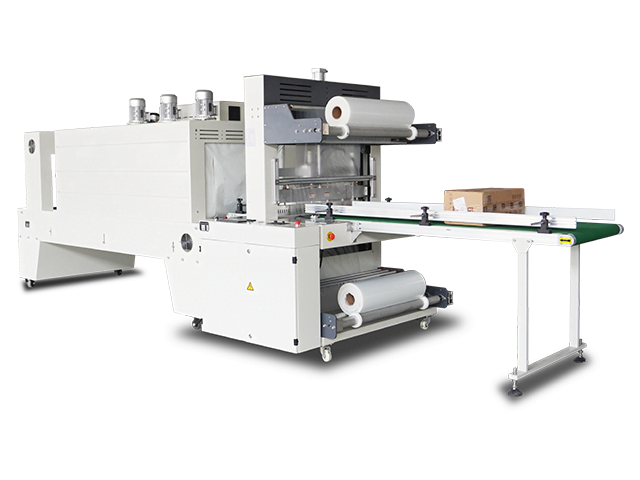

Automatic side sealing shrink packing machine including box motion side sealing shrink tunnel machine, side sealing shrink wrapping machine and double sides shrink wrap machine which are widely applicate in paper, printing, food, cosmetic, medicine, ladder, floor industries. Machines adopt PLC touch screen control, operation can be done on the screen, machine with high production efficiency and easy to use. Side sealing knife can be sealed continuously, the product packaging length is infinite, and the height of the side sealing knife can be adjusted by hand wheel. Infeed conveyor and output conveyor are available according to product needs.

Automatic L sealer shrink packing machine including high quality type and economic type which are widely applicate for shrink wrapping single or group packaging of thermal sensitive paper, food, stationery, beverage bottles, cosmetics, spray cans, medical supplies, brake pad, filter, appliances, boxes, paper trays, paper bowls, paper cups, A4 paper and other products.

Automatic sleeve sealer shrink packing machine including straight line feeding conveyor type and 90 degree feeding conveyor structure, the machine material can produce carbon steel and stainless steel to meet different industries requirements. Shrink bundle wrapping for the tray products such as: water bottles, milk cans, beer bottles as well as logistics foam boxes, cartons, cable coils, tyres, tapes, cylindrical products. Single row or multi row feeding heat shrinkable packaging for mineral water bottles, beverage bottles, beer bottles and other bottles. It can be connected with filling machine and labeling machine.

Non standard customized products are products designed, produced, and processed according to specific user needs. Unlike standard products, non-standard customized products can be fully customized according to the needs of users, in order to better meet their needs and solve their actual problems.